Industry News

Envicool liquid cooling quick coupling improves the full chain efficiency!

Currently, liquid cooling technology is developing rapidly. Envicool Coolinside full chain liquid cooling solution has helped some leading Internet companies and financial communications industries to complete liquid cooling technology pilots, assisting the popularization of liquid cooling data center and promoting it in the direction of green energy saving.

In the liquid cooling data center, Envicool liquid cooling quick couplings can realize quick connection and disconnection between devices without leakage, reducing unnecessary workload caused by liquid draining and injection. It protects various sensitive electronic components from being corroded by coolant in the data center, while achieving efficient temperature control.

Quick plug and unplug: efficient installation and maintenance

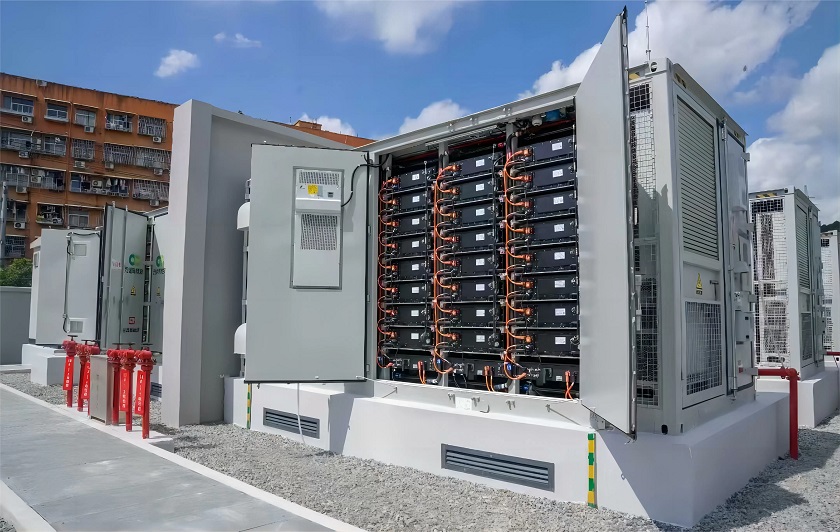

Taking the use in energy storage application scenarios as an example, for traditional battery maintenance, it takes 2 people 6 hours to complete a series of processes such as draining, vacuuming, filling, and exhausting. While, by applying Envicool liquid cooling quick couplings, there is no need to shut down the system. Only a single node needs to be maintained, which can achieve environmentally friendly quick replacement in 30 minutes, quickly improving maintenance efficiency.

Sealing and no leakage: safe and reliable throughout the life cycle

Envicool liquid cooling quick coupling adopts welding-free sealing technology to further improve the liquid cleanliness in the pipeline. There are 2 locking models: steel ball locking structure design and direct insertion automatic locking, equipping with strong corrosion and impurity resistance. It is fully sealed and no leakage, ensuring the safety and reliability of the equipment throughout the life cycle.

Four-dimensional integration: compatible and unified performance across the full chain

In terms of server liquid cooling, the quick coupling is an important part of Envicool Coolinside full chain liquid cooling solution. The solution relies on the quick coupling to achieve "end-to-end, full-chain" advantages, effectively improving system energy efficiency and reducing operating costs. With the "four-dimensional integration" of independent R&D, production, delivery and service, we ensure the reliability of products and solutions, helping customers "achieve zero risk".

Customized services: meet different customer needs

In order to meet the needs of different application scenarios, each series of Envicool liquid cooling quick couplings has a variety of diameters and materials, and it is suitable for different working medium. It can adapt to the different application scenarios according to different working flow, pressure, temperature and product material, etc. Meanwhile, it can meet the different installation needs of customers through customized interface methods.

It is worth mentioning that Envicool liquid cooling quick couplings have undergone two and a half months of testing and successfully passed xFusion’s product quality inspection. This fully confirms Envicool excellent product performance and industry strength.

Relying on 4 major independent technology platforms, 2 national-level testing centers and 7 major bases across the country, Envicool ensure product reliability and respond to customer needs with high-quality products actively with strong R&D strength and production capabilities.

In the future, Envicool will develop and launch high-quality products efficiently through continuous technological innovation, complete supply chain system, and a marketing service network covering China and key regions around the world, creating new value for customers.